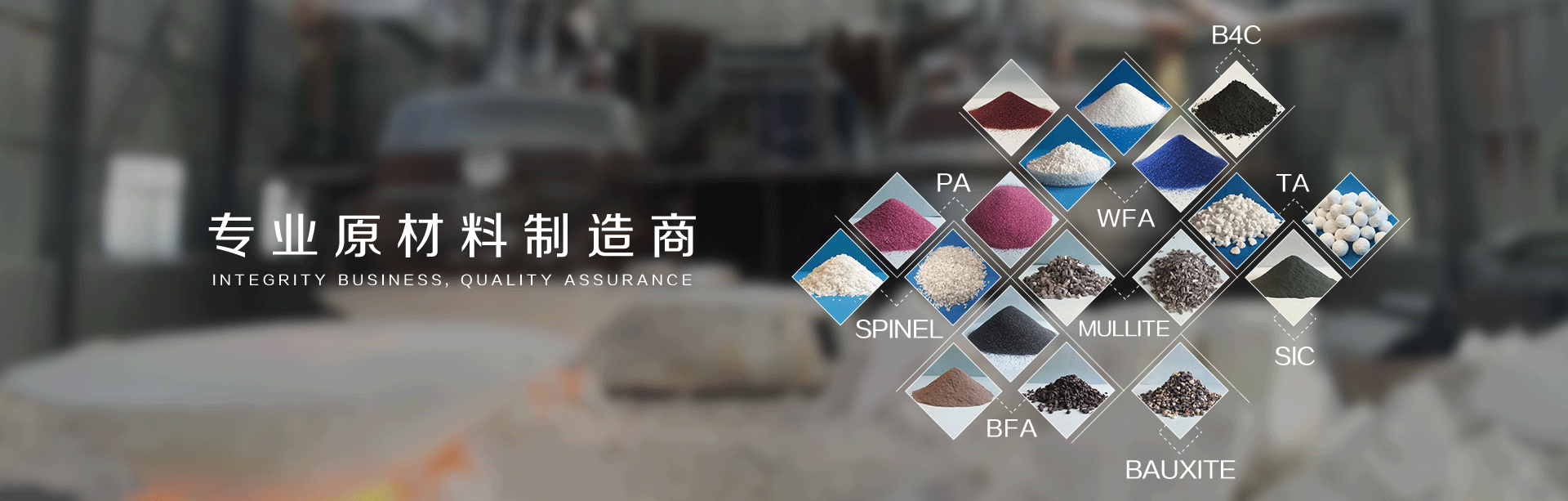

1.Description:

Sintered Spinel is made of industrial alumina and high purity caustic-calcined magnesite powder by high pressure sintering and fine grinding in UHT converter.

2.Characteristics:

It characterized with high hardness, small coefficient of thermal expansion,thermal shock stability etc.

3.Application:

It’s ideal raw material of ladle castable and magnesium spinel bricks. It’s extensively applied to the lining of converter,glass kiln, open hearth, casting ladle etc.

4.Specification:

Items | Unit | MAS 66 | MAS 78 | |||

Guarantee Value | Typical Value | Guarantee Value | Typical Value | |||

Chemical Composition | Al2O3 | % | 64-67 | 65.7 | 74-79 | 77.2 |

MgO | % | 32-35 | 33.3 | 20-25 | 21.8 | |

CaO | % | 0.60 max | 0.39 | 0.6 max | 0.26 | |

SiO2 | % | 0.40 max | 0.25 | 0.4 max | 0.25 | |

Fe2O3 | % | 0.50 max | 0.31 | 0.5 max | 0.31 | |

Na2O | % | 0.10 max | 0.04 | 0.3 max | 0.18 | |

Magnetic | % | 0.02max | 0.01 | 3.2 min | 3.26 | |

Bulk Density | g/cm3 | 3.2 min | 3.26 | 1850 max | 1800 | |

Refractoriness | ℃ | 1850 max | 1800 | 1 max | 0.5 | |

Absorbing Water Rate | % | 1 max | 0.5 | 5.0 max | 3.2 | |

Porosity Rate | % | 5.0 max | 3.2 | 74-79 | 77.8 | |

Grain Size | mm | 8-5, 5-3, 3-1, 1-0 | ||||

Fine Powder | mesh | -220, 325F | ||||